Metal 259 - Fall-1998 - Exam 2

Par time - 16 min. (Time required to read questions, think, and write answers)

Only answers placed in the space provided will be considered.

Diagrams and drawings, where appropriate, are welcome.

1. (0) Put your social security no. on the line above now.

2. (10) Two ways in which a dislocation moving through a matrix can interact with a tiny precipitate particle (show a diagram of the interaction effect for each):

a.

b.

3. (12) List all of the phases that can be present in steels (do not include the alloy carbide phases or consider stainless steels) and briefly describe how each can be formed. (The number of answer spaces below exceeds the number of answers required.)

a.

b.

c.

d.

e.

f.

g.

4. (6) For the phases listed in problem 3, which ones can occur in:

a. hypoeutectoid steels

b. hypereutectoid steels

c. a eutectoid steel

5. (10) Comment briefly on the possibility of age hardening in each of the alloy systems depicted by the partial phase diagrams below. Give the reason why age hardening is or is not possible in each case.

6. (10) What is the appropriate hardening procedure for a tool made of A2 tool steel (1C-0.6Mn-5.25Cr-0.25V-1.1Mo)? Tell why for each step.

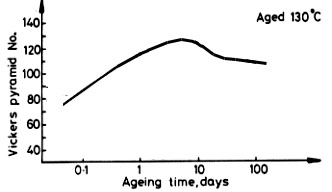

7. (7) Below is a curve which describes the hardness of an age hardening aluminum alloy as a function of ageing time at 130°C.

a. Describe what is happening inside, structurally, the material up to an ageing time of about 7 days. (Don't talk about properties.)

b. a. Describe what is happening inside, structurally, the material at ageing times of greater than 7 days. (Don't talk about properties.)

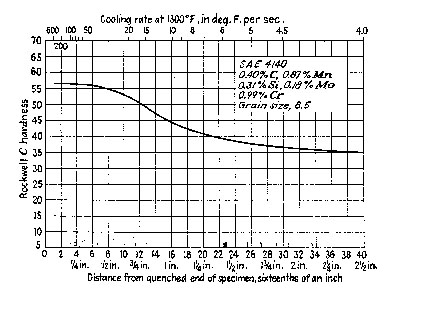

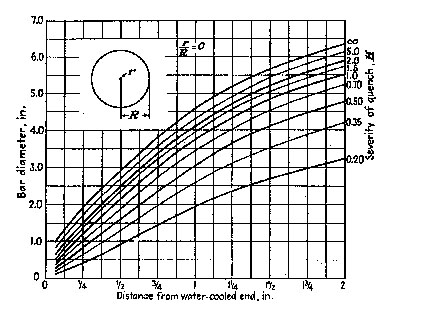

6. (8) What is the hardness at the center of a 3" diameter 4140 bar when quenched at a severity of 0.20? Show your procedure on the curves below.

Ans:________

7. (9) List some common types of cast irons. Describe the differences in their microstructures. Comment on their mechanical properties.

8. (10) Two steels, one with very low hardenability and one with high hardenability, are to be case hardened. One will be pack carburized and the other induction hardened. Match the steel with the case hardening method and describe the reason(s) for your choices.

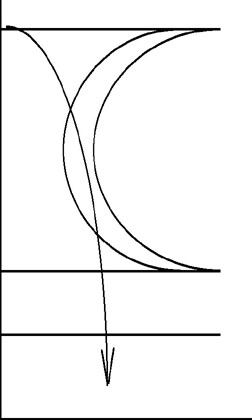

9. (10) For the quenching curve shown below on the isothermal transformation curves for a steel, what phase(s) result after quenching? Why?

Ans:________________

10. (8) Austenite is only found in the Fe-C phase diagram at temperatures above 723°C, yet there are several instances when AUS can be found in steels at room temperature. Describe these and discuss how this can happen.