1. Why are steels used so extensively?

iron is allotropic

2. What is the composition of a 4140 steel?

0.40 carbon 0.77 Mn 0.98 Cr 0.21 Mo -

according to table in notes, page 6: 41xx are 0.50Cr-0.12Mo or 0.95Cr-0.20Mo

3. Suggest a reason why rivets made of a 2017 aluminum alloy are refrigerated until they are used.

2017 similar to 2024 (Al-4.4Cu) age hardening alloy

want rivets to be soft for heading operation - after heading want strength

to increase markedly

after solution treatment atabout 500 C, apparently have to refrigerate alloy

to keep it from ageing

so rivets stay soft until after heading

alloy ages at room temperature

4. Compare age hardening of aluminum alloys and the quenching and tempering of steel with respect to the processing steps. How do the mechanical properties change during each step for both types of alloys.

Q&T and Q&A have same type of temperature

changes - i.e., heat to relatively high temp., quench, reheat to low temp.

for Q&T, at high temp. mat'l is soft. after quench mat'l is glass brittle.

after tempering, incredibly tough

for Q&A, mat'l is soft at high temp, soft after quenching, strong after

ageing

5. What is the purpose of annealing an alloy?

to soften it

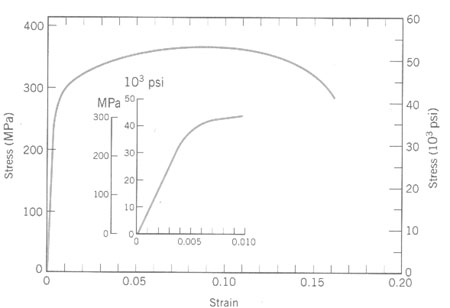

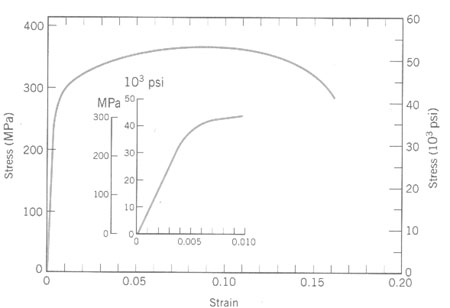

6. Determine yield strength, modulus of eleasticity, tensile strength, elongation, for data given below.

YS = 41 ksi at 0.2% offset, UTS = 53 ksi, elongation

= 15.7% (don't include elastic deform.)

modulus = slope of elastic portion = 18ksi/0.002 = 9000 ksi

7. Suppose a metal piece has a dislocation density of 104 /mm2. If all the dislocations in 1 cc of the material were somehow removed and linked end to end, how long would this chain be? If the materials was cold worked so that the dislocation density increased to 1010/mm2, how long would the chain be?

To estimate, assume dislocs in 1 cc cube are all

1 cm long and terminate on one face of cube

to give stated density. total no./sq. cm = density x 100. Answers are then

106 cm and 1012 cm -

6 mi and 6 million mi.!

8. Describe these strengthening mechanisms and the role that dislocations play in each:

grain size reduction

disloc pileups against grain boundaries.....more grain

boundary material in small grained mat'ls

strain hardening

work hardening - dislocation entanglements. deformation

produces so many new dislocations that they become entangled.

solid solution hardening

atom size differences give distorted slip planes -

disloc motion is retarded

precipitation or age hardening

dislocs hang up on tiny precipitate particles whose

slip planes (if there are any) are in the wrong orientation wrt to slip

planes in the matrix mat'l or crystal structure of precipitate is too complex

for well-defined slip planes