Analysis of Methods to Prevent Type B Lüders Band Formation

In order for 5XXX series aluminum alloys to be used in automobile body

panels, a practical and effective method for preventing type B Lüders

bands must be developed. From the information gathered

on the causes of Lüdering, many possible methods of preventing them

have been developed. Of these

many possible solutions only a few show real potential after practical

manufacturing considerations are taken in to account.

Increasing the grain sizes above

0.05 mm (50 µm) will effectively prevent type B Lüders band formation

(Phillips, Swain, and Eborall 1952), but this solution becomes less attractive

as processing realities are considered. Typical grain sizes for cold rolled

and recrystallized aluminum sheet are between 6 and 10 µm (Vetrano,

Lavender, Hamilton, Smith, and Bruemmer, 1994). Increasing the grain size

to the 50 µm needed for preventing the Lüders line formation

will have an adverse effect on the formability of the aluminum sheet, and thus, it is not a practical solution.

Controlling the texture, or preferred orientation of surface grainsjust surface grains?? in a material, appeared to be a promising method for controlling Lüdering. In a single crystal Al - 0.3% Mg alloy, Lüdering was found to occur in only when tested in one orientation (Tabata, Fujita, and Ueda, 1980). This information may not lead to a practical solution because of the way automobile body panels are formed. These panels are formed through deep drawing, a process in which deformation is done in all directions surrounding a central point. So, although controlling texture may be used in preventing Lüders in a unidirectional tension test, the radial deformation used to produce body panels for automobiles eliminates texture as a possible solution.a good argument, but maybe somewhat oversimplified wrt deformation directions in drawing

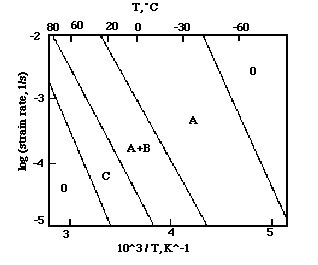

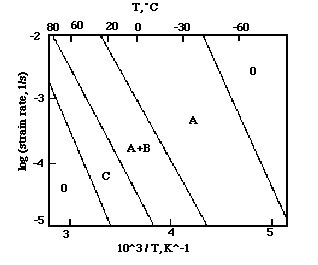

Altering the temperature and strain rate at which an alloy is formed

is one good possibility for the prevention of type B Lüders band formation.

Robinson and Shaw (1994) report that the serrated

yielding which results in Lüders bands occurs only within certain strain rate and temperature ranges which

depend on temperature.(see Figure

1) shows these regions

as plotted against strain rate and temperature. The regions marked

C, A+B, and A are regions where different types of serrated yielding occur

on the stress - strain curve. The regions marked zero are where no serrated

yielding or Lüders bands occur. This figure

shows that at higher temperatures, higher strain rates can be used for forming

without Lüders band formation.

Figure 1 Temperature and strain rate dependence of serrated yielding which results in Lüders band formation. (From Robinson and Shaw (1994).)

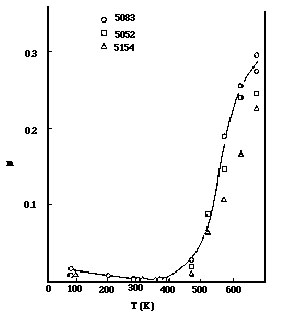

In 5XXX series alloys, strain rate sensitivity (m) is an important in

understanding under what conditions Lüdering will occur. The equation

for strain rate sensitivity is where is the strain rate. Lüdering occurs

when m is negative or near zero. Figure 2 shows the effect of temperature

on strain rate sensitivityfor 3 5XXX alloys.

In the region from 100 K to 400 K m is very small and so the alloys are very susceptible to Lüdering.

Above 400 K, however, m increases very rapidly with increasing temperature.

. Figure 2 The effect of temperature on strain rate sensitivity. (From Lloyd (1980).)

For the reasons shown in the preceding paragraphs adjusting the temperature and strain rate at which the parts are formed might provide an acceptable solution to the Lüdering problem. Finding the proper adjustmentconditions?? might be difficult, however. The temperature needed to achieve a suitable strain rate for manufacturing might be unreasonably high. If the temperature needed is too high, extra processing equipment and steps might be needed which would make this solution unattractive for economic reasons.

Another possible solution which looks very promising is the alteration of the composition of an existing 5XXX series aluminum alloy. Lüdering occurs because Mg diffuses to the grain boundaries and pins mobile dislocations for a while and then allows them to break free, forming a Lüders band. A preliminary idea on how to stop Lüders band formation is to lower the Mg content so there is not as much free to diffuse to the grain boundaries and pin the dislocations.

The amount of free Mg can also be controlled by adding other alloying elements. Mg2Si and Cr2Mg3Al18 are typical phases present in 5XXX series aluminum alloys (Stevens, 1985). To help use up more of the free Mg, the addition of more Si and Cr to help form these phases is being explored. The possibility of adding other elements which are not currently present to help use the Mg is also being explored. The only potential problem with this method that must be considered is that the removal of the free Mg may have a negative impact on the desired mechanical properties. Removing the free Mg may make the alloy less work hardenable, which is the reason 5XXX series alloys are more desirable than the age hardenable 2XXX and 6XXX series aluminum alloys.decreased solution hardening..........so haw do we compensate for this??

REFERENCES

LLOYD, D. J., Metall. Trans. A, 11, 1287 (1980)

PHILLIPS, V. A., SWAIN, A. J., and EBORALL, R., J. Inst. Met., 81, 625 (1952)

ROBINSON, J. M. and SHAW, M. P., Int. Mater. R., 39, 113 (1994)

STEVENS, R. H., Metals Handbook Vol. 9, edited by MILLS, K, ASM, Metals

Park,

OH, p. 359 (1985)

TABATA, T., FUJITA, H., and UEDA, N., Mater. Sci. E., 44, 81 (1980)

VETRANO, J. S., LAVENDER, C. A., HAMILTON, C. H., SMITH, M. T., and

BRUEMMER, S. M., Scr. Met. Mat., 30(5), 565 (1994)